Split Cable Transit, UL Type 12/4X* / IP66

Grommet based cable entry for standard cut-outs of heavy industrial connectors. Available as single or double row version.

» KEL-ER CR

A cleanroom is a room that has an extremely low concentration of airborne particles. Airborne particles are all particles and substances that are suspended in the air and for the most part cannot be seen with the naked eye. icotek cable entry systems for cleanrooms are suitable and certified for class 1 in accordance with ISO 14644-1. Find out more »

Grommet based cable entry for standard cut-outs of heavy industrial connectors. Available as single or double row version.

» KEL-ER CR

Grommet based cable entry frames suitable for cut-outs of heavy industrial connectors. Available as single or double row version.

» KEL-U CR

Split cable grommets for diameters of 1 to 17 and 16 - 35 mm. Suitable for KEL CR cable entry frames.

» KT CR

Split cable grommets for diameters of 1 to 8 mm. Suitable for KEL CR cable entry frames.

» KT CR multi

Gland plate with high cable density and certified protection up to IP66 / UL Type 12. Available in various sizes.

» KEL-DPZ CR

Round gland plate with certified sealing IP66/IP68 / UL Type 12/4X*. Metric threads M25-M63.

» KEL-DPZ CR round

Round hygienic gland plate with certified sealing IP66/IP68. Metric threads M32-M63.

» KEL-DPZ-HD CR round

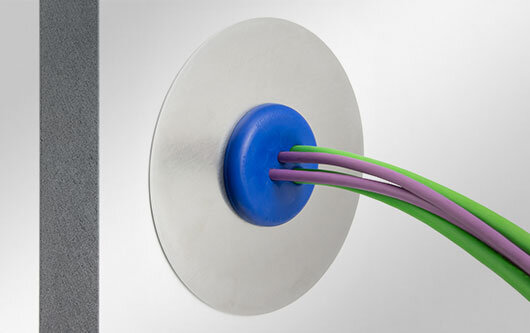

The cover panels have an outer diameter of 150 mm and a center hole of 32.5 mm, 50.5 mm or 63.5 mm to accommodate the thread extensions, cable entry plates & split cable glands.

» AB-MSuch cleanrooms are needed wherever particles present in the ambient air would disrupt production. This is the case, for example, in medical technology, semiconductor production, microsystems technology, pharmaceuticals, aerospace technology or optics. Cleanrooms are also needed in medical research.

Cleanrooms are classified by classes according to ISO 14644-1 as per ISO 1 to 9. The individual cleanroom classes may only contain a certain number of particles of a specified size. The particle concentration is considered per m³ of air. ISO 1 contains the strictest specifications, for ISO 9 the lowest specifications.

In order to be able to meet these strict requirements, materials specially developed / modified by icotek are used in our certified clean room products.

All icotek cable entry systems for the cleanroom tested and certified by the Fraunhofer IPA are suitable and certified for class 1 in accordance with ISO 14644-1!

++ mandatory | + recommended, but not mandatory | 0 generally not required but in individual cases recommended (Source: Fraunhofer IPA)

icotek recommends cleaning products installed in cleanrooms with a mixture of 70% isopropanol and 30% distilled water.

Cleanrooms must be cleaned of contamination with microorganisms, particles and pyrogens before each commissioning or after maintenance work. An effective method is cleaning by vaporizing hydrogen peroxide (H2O2). The hydrogen peroxide is converted into a gaseous state and the subsequent microcondensation results in optimum decontamination throughout the entire room and on all surfaces.

icotek has subjected its cable entry systems to the H2O2 cleaning process and can recommend its use. A declaration of conformity is available on request from product management: pm@icotek.com

Not only the particle emissions are relevant but also the outgassing values VOC (Volatile Organic Compounds)/SVOC (Semivolatile Organic Compounds) of the products used in clean rooms. This applies in particular to the semiconductor, optics and aerospace industries.

In the ISO class, the air cleanliness classification works on the basis of the particulate concentration.

In the ISO-ACC class, air cleanliness works on the basis of chemical concentration. The chemical concentration can lead to a chemical contamination, which can have a damaging effect on the product or on the process.

Materials as well as cable entry systems are classified based on their chemical concentration.

ISO-ACCe Class (x) = ISO-Air Cleanliness chemical concentration for equipment = AMC Class Equipment

ISO-ACCm Class (x) = ISO-Air Cleanliness chemical concentration for material = AMC Class Material

The Fraunhofer IPA certified values that were in part no longer measurable in the ultra-trace range and thus excellent to very good values. The material-specific emission rate (= ISO-ACCm class) was determined. The smaller the ISO-ACCm class, the lower the material-specific emission rate.

The test certificates of the Fraunhofer IPA can be requested from icotek: pm@icotek.com